ON-LINE LUBRICANT AERATION MEASUREMENT

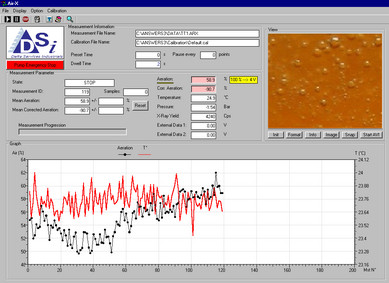

Air-X is a new instrument designed for on-line monitoring of oil aeration in a running mechanical system (engine, gear box, etc.). The operating principle is based on an accurate density measurement using X-ray transmission. An oil sample coming from the mechanical system is circulated continuously into a compact measuring chamber where the density measurement is performed.

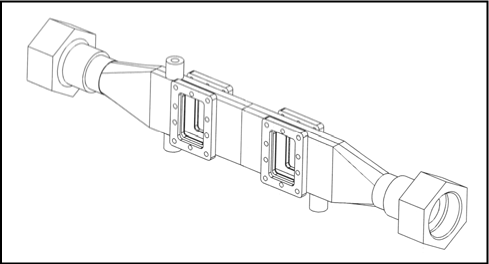

The specific chamber design of Air-X allows the instrument to perform on-line measurements using a very low activity X-ray source. The chamber is self-shielded so that no radiation at all comes out from the unit whatever the operating conditions.

The total volume of oil sampled in "Air-X" is less than 0.5 liter for a minimal impact on the operating mechanical system.

The chamber includes probes that are used for automatic temperature and pressure compensation.

Therefore, the air content can be computed and displayed at standard conditions

(i.e. T = 20° and P = 1 bar).

The core of Air-X is a compact measuring chamber with 2 windows: one is used for the X-ray transmission measurement, the other for the visualisation of the oil flow via a video system.

Air-X is a new instrument designed for on-line monitoring of oil aeration in a running mechanical system (engine, gear box, etc.). The operating principle is based on an accurate density measurement using X-ray transmission. An oil sample coming from the mechanical system is circulated continuously into a compact measuring chamber where the density measurement is performed.

Basically, aerated oil is supplied at atmospheric pressure, in such a way that the dissolved air fraction is limited to a few percent. There is also a possibility to increase pressure in the output line in order to increase the ratio (dissolved/undissolved air) up to 100%. Maximum output pressure of the generator is 10 bars. Oil temperature is regulated in a range between 0°C and 150°C.

To cover a wide range of applications, the aeration measurement can be performed either directly in the output line of the generator, or at a selected point in the mechanical system under test. Whatever the sampling point, the generator will increase automatically the aeration level in the supply line until a pre-defined value is reached at the sampling point.