Automatic T° Compensation

During engine operation, temperature changes induce density variations.

Without compensation, any temperature increase would increase the

dilution signal since for the same lubricant activity the total

volume is higher, and vice-versa.

It is thus important to take into account those density variations.

A temperature measurement is performed in the measuring chamber in order to

correct the dilution measurement, using the following formula:

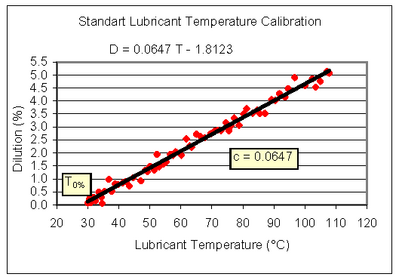

Dcorr = D(T)-c(T-T0%)

Where :

Dcorr is temperature corrected dilution

D(T) is dilution at a measured temperature

c is the temperature calibration coefficient

T

0% is a reference temperature for 0% dilution

A calibration measurement has to be performed in order to determine coefficient c.

The calibration consists of circulating labelled but non-diluted lubricant in the measuring chamber,

and measuring specific activity variations associated to temperature changes. Activity variations are

expressed in terms of oil dilution and calibration typically yields a first-order curve

where the slope is the above-mentioned coefficient c.

The reference temperature T

0% is

the starting point of the curve. Such calibration has to be performed once per type of lubricant.