What is On-Line SLA?

A thin layer and pre-selected area of

the surface of a machine component is

labeled with radio-isotopes. Once the

activated part has been installed and

the machine reassembled, specific

measuring equipment can detect the gamma

rays emanating from the activity.

During the wear or corrosion

process, the loss of material results in

a loss of activity at the surface of the

part and an accumulation of activated

particles in the lubricant. By placing a

gamma ray detector near the activated

component or near the lubricant circuit

reservoir or filter, the movement of the

activity is very precisely measured.

These measured values are

computer-processed rapidly, and the

on-line monitoring of the degradation is

delivered.

The system is

able to deliver a non-contacting and

continuous measurement of wear and

corrosion, even for parts at

inaccessible locations. The results are

extremely precise

(0.1µm--0.01µm). Moreover,

the exact location of the loss is known.

The measurements are performed under

real operating condition.

MAIN FEATURES

Very high sensitivity ==>

Faster development

On-line measurements ==>

Dynamic studies

Selective labeling ==>

Exact localization of wear

Remote measurements ==>

Study inaccessible locations

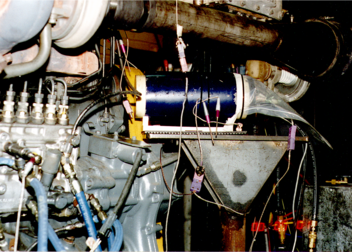

Residual Method (aka Direct or TLD)

This method consists of placing the

detector near the activated component's

labeled zone. The activity can be

detected through the engine wall. As the

activated material is removed from the

zone, the activity decreases. This loss

of activity is then converted on-line

into the equivalent material loss.

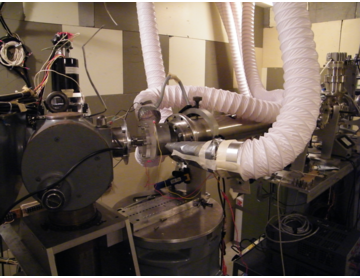

Flow-Through Method (aka Concentration or Debris)

This method is used when the wear

particles can be collected in a

lubricant circuit. The increasing amount

of activity in suspension in the

lubricant is monitored, or the wear

particles are captured by a filter or a

magnet. This increase of activity is

then converted on-line into the

equivalent material loss.

Activation Services

ANS Technologies operates its own

activation facility at the University of

Montreal. We are equipped to perform

proton, deuteron and heavy-ion

activations on a wide variety of

components, materials and geometries. We

also cooperate with other facilities to

provide additional services of neutron

activation, Be implantation, specialized

profiles, and heavy targets.

Track-Wear Products

In order to perform SLA tests, a variety

of equipment is required. ANS

Technologies has developed most of the

equipment that we use, and these

products are available for purchase and

rental for in-house users of SLA. These

products include:

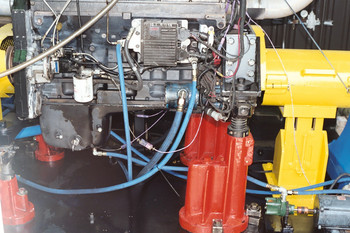

On-Site Services

ANS Technologies has personnel who travel across North America performing SLA

tests at the customers' facilities. Our personnel are available both short and

long term, at very reasonable prices. We pride ourselves on providing the best

support possible. Your test is our test !

Off-Line Applications

Off-line applications can be performed for interested customers. ANS performs

the activation of the needed components and sends them back to the customer.

Once the experiment is completed, the components are sent back to ANS. Residual

measurements are made, and the results are fully described in a written report.

Service Packages

Service packages are available to meet the customer's specific needs. Some

typically examples are:

- Full Service Package: all aspects of the

test, including planning, activations, on-site testing, radioactive material

logistics, data analysis and a final report.

- Routine

Application: Sale or lease of equipment, activations, test procedures,

consulting, training.

- Activation Service: components are

activated, measured & shipped. Activity-Depth profile is provided.

- Consultancy Services: provided either from our center, or at the

customer's location.